Plastic recycling is broken – New plastic alternatives key in fighting microplastics

Recycling and reuse alone can’t tackle the problems caused by rising plastics production volumes. A wide-ranging approach with the reduction and replacement of plastics is required. Luckily, plastic alternatives with serious environmental and business potential are emerging.

In the past few years, the sorting of plastics for recycling has become a natural everyday chore for many individuals and organizations willing to do their part for the environment. This is obviously a good trend. Few people, however, know what happens to the plastic when the garbage truck speeds away.

In this blog, we’ll discuss the problems and development potential of plastic recycling and the tools we have available for tackling the global plastics problem.

Recycling can’t cope with rising plastic production volumes

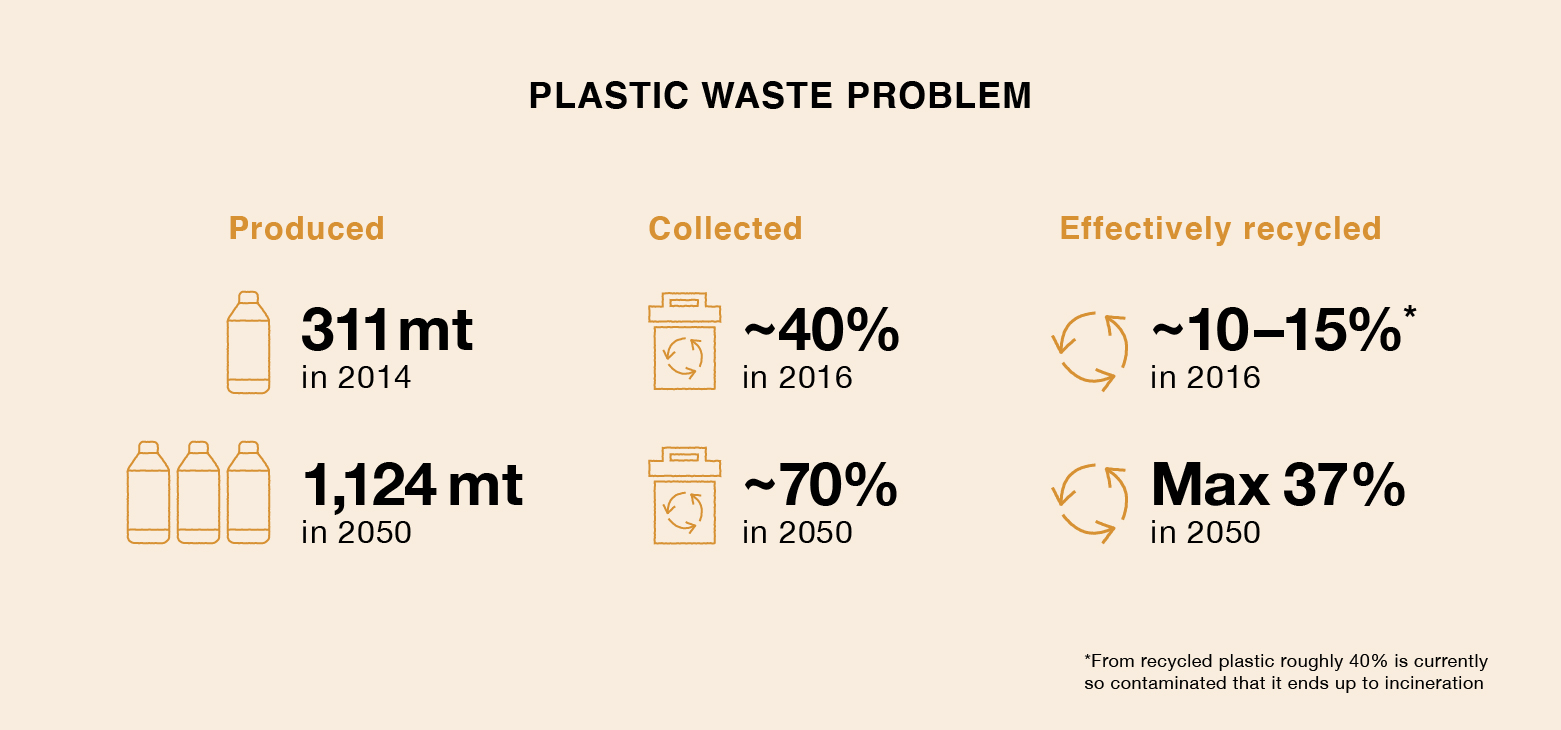

The production of plastic is expected to at least triple by 2050. As the existing recycling infrastructure can’t handle even our current production levels, the amount of microplastics released into nature is about to grow significantly. Increasing and diversifying the global recycling capacity is a necessity, but there are also several problems that prevent recycling from being the sole answer to the rising plastics production.

Mechanical recycling

Mechanical recycling is currently the only recycling option for plastics. While it’s important to collect plastic for reuse, mechanical recycling has its limitations:

- Not all plastics collected from households can be recycled with mechanical recycling. This results in plastic being burned for energy.

- Many plastic types are not recycled due to their low volume. Even if the materials could be separated and recycled, it often isn’t economically viable.

- Plastics are becoming increasingly complex and multilayered, which makes it hard for mechanical recycling to separate the different parts for reuse.

- In mechanical recycling the chemical polymer remains the same and the quality of plastic gradually decreases. You can only recycle the same piece of plastic a few times before the quality is no longer sufficient for reuse.

- Cheap, fossil-based virgin plastics are cheaper to produce than they are to collect, clean and process. This reduces market opportunities for recycled plastic.

- Some policy makers have relied on exporting plastic waste to low-income countries instead of building a sufficient recycling infrastructure.

Chemical recycling

Currently, the dominance of mechanical recycling slows down the development of chemical recycling processes and the required infrastructure. The technological solutions for chemical recycling already exist, but it isn’t considered an official recycling option yet. However, chemical recycling shows a lot of potential.

In chemical recycling, the polymers of the collected plastics can be changed, enabling the improvement of existing polymers. This process is called upcycling. In the future, transforming carbon-rich polymers to desired materials would bring possibilities for both conventional plastics as well as new bio-based material.

Instead of relying on mechanical recycling, all forms of recycling should play their part in creating a functioning recycling infrastructure.

Plastic recycling doesn’t solve microplastics released during use

On top of the end-of-life challenges, microplastics create problems during their whole life cycle. Car tires and synthetic textiles, for example, release microplastics every time we use them. This way microplastics find their way to the water we drink, the air we breathe and the soil we farm . As a large share of microplastic pollution is wear-related, handling the end-of-life problems through recycling isn’t enough.

These mechanical, technological, financial and political problems regarding recycling are a blow to the global need to reduce microplastic contamination in nature. In 2016, 14% of plastic waste was recycled sufficiently globally. Around 40% of all plastic that is collected for reuse ends up incinerated instead. It’s clear that other means must be considered to supplement recycling.

A holistic toolbox for a healthier future

Fighting plastic waste calls for a wide-ranging approach where recycling plays its important part. The traditional formula for a better future used to be ‘reduce, recycle, reuse’. We don’t think this is enough. A new element needs to be added: replace. Let’s go through the four Rs and their roles:

Reduce: With plastic production volumes skyrocketing, it’s paramount that global policy measures are taken to cut back on fossil-based plastics.

Reuse: Reusing plastic is possible from individuals to nations. Individuals can easily reuse plastic containers, for example by freezing food in them or by filling empty soda bottles with fresh water. At a larger scale, cities and nations can reuse plastic bottles, for example, multiple times before the bottles reach their end of life.

Recycle: Most plastics can’t be reused easily. A versatile recycling infrastructure capable of dealing with complex plastics in an efficient way would significantly reduce the worsening microplastics problem.

Replace: Let’s face it, plastic has functions that are integral to our modern way of life. However, we must find more sustainable alternatives for fossil-based plastics if we want to keep our planet healthy.

Plastic alternatives show serious environmental and business potential

In a time when policymakers are getting increasingly interested in sustainability and carbon footprint, there are various ways to make a difference for both individuals and businesses. Environmentally friendly plastic alternatives are no longer an expensive sidetrack but rather a serious business advantage that attracts customers.

At Sulapac, we are on a mission to save the world from plastic waste – and microplastics. We want to ensure that you don’t have to worry about using packaging or compromise in product quality in favor of being eco-friendly. When you use Sulapac, we promise you:

Beauty: Sulapac has a unique look and feel with fine visible wood chips that make it stand out. Companies appreciate the ceramic sound and finish of our materials. Consumers can feel that Sulapac is not conventional plastic.

Functionality: Sulapac is premium quality and mass-producible with your existing plastic product machinery. It meets demanding technical requirements and is suitable for various applications, including luxury packaging and food contact products.

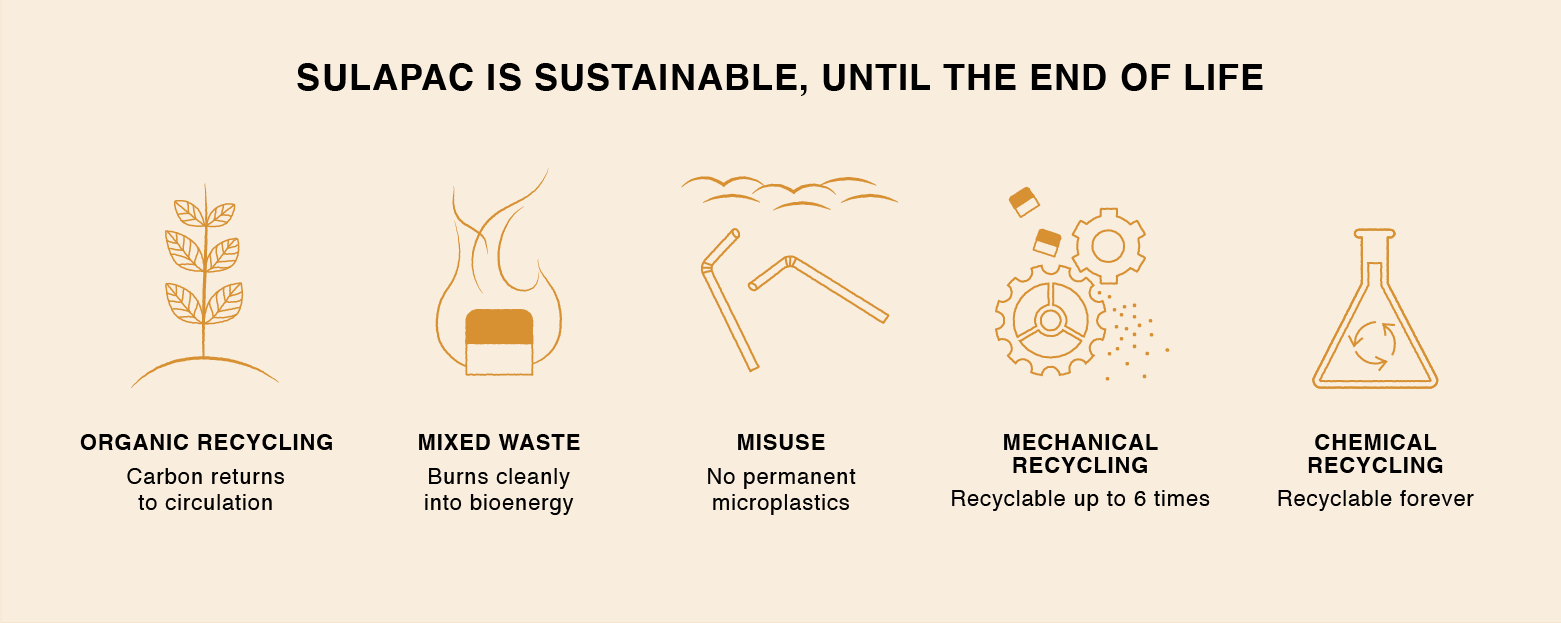

Sustainability: Sulapac is biobased and has a low carbon footprint. The material biodegrades without leaving permanent microplastics behind and thus reduces plastic pollution. It’s made of responsibly sourced raw materials, such as wood chips from industrial side streams that originate from certified forests. Sulapac is industrially compostable and can be recycled both mechanically and chemically. The material can be mechanically recycled six times without it losing its mechanical properties.

It’s time to switch from environmentally detrimental plastic types to sustainable alternatives. Are you ready to replace pollution with a solution?

This blog is the third part of our microplastics series. Have you already read the first two?

❶ Defining plastic – What is it and how should we change the way we conceive it?

❷ Demystifying plastic types – How to navigate the complex web of seemingly eco-friendly plastics

Do you want to explore Sulapac’s beautiful, functional and sustainable materials?