Renewable revolution: why Sulapac’s bio-based materials have endless possibilities

Sulapac’s bio-based materials are not only a planet-friendly option. They are also easy to adopt, applicable across diverse industries, and aesthetically pleasing. Let’s look at how Sulapac makes sustainability a simple choice for brands and manufacturers – today and in the future.

Why the market for bio-based material is growing

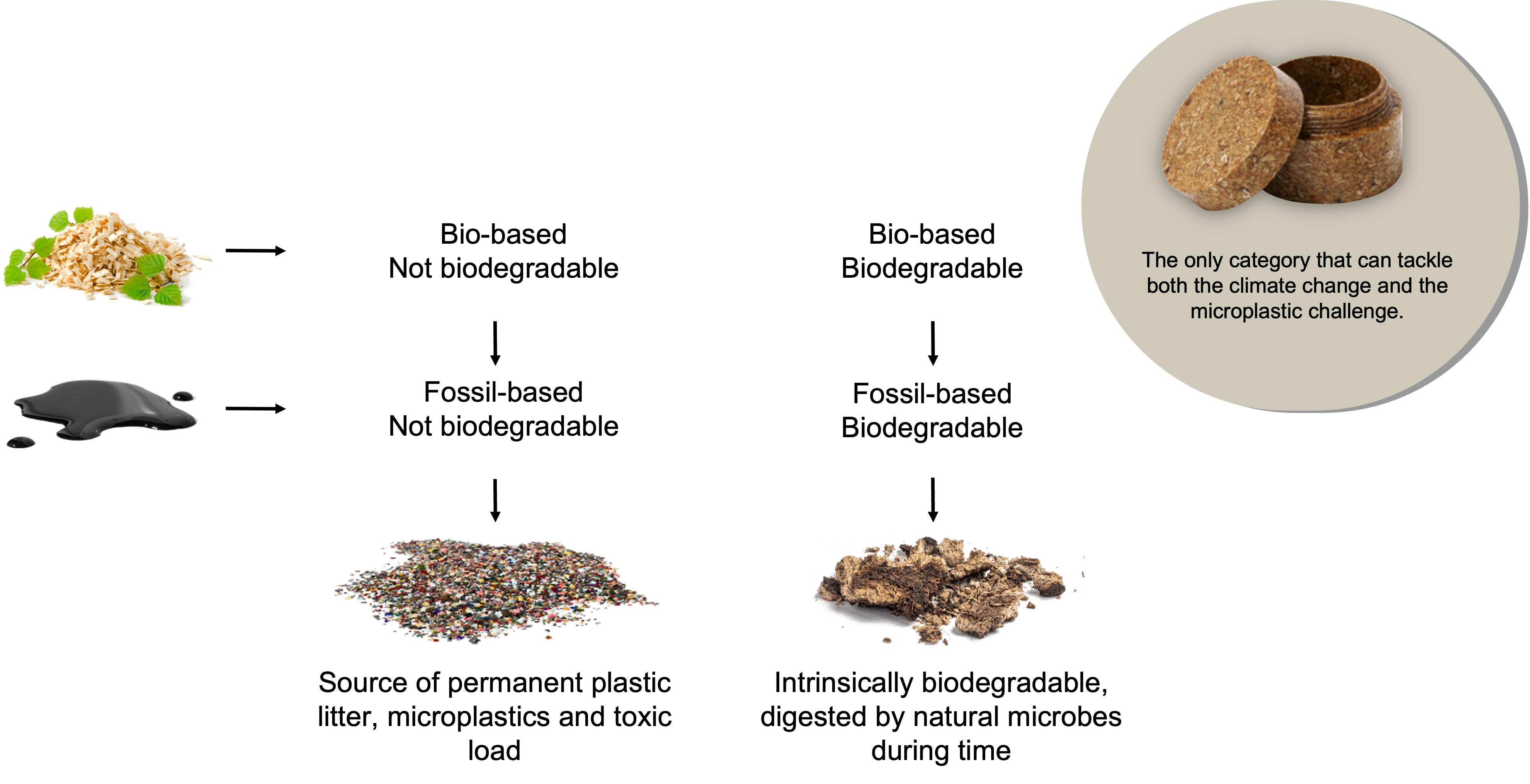

Switching from traditional petrol-based plastics to bio-based recyclable materials is vital to tackle plastic waste and halt the spread of dangerous microplastics throughout the environment. Several factors are spurring the impetus to drive bio-based materials to the forefront of sustainable production.

As consumers become increasingly environmentally conscious, they are actively seeking to make choices that have a lower impact on the environment. Bio-based materials – recyclable, compostable, derived from natural sources – offer a sustainable alternative to traditional plastics made from fossil fuels.

At the same time, manufacturers and businesses are seeking greener ways of creating and using products. Stringent environmental regulations, concern about the negative impacts of plastics, and supply chain volatility of fossil-based materials – all factors that play a part in driving companies to choose sustainable alternative materials.

Finally, technological advancements have propelled bio-based materials’ maturity and scalability – meaning that choosing sustainable alternatives has never been easier.

This convergence of technical innovation, consumer demand for eco-friendly options, and industry awareness of environmental issues drives the rapid growth of the bio-based plastic alternatives market.

Why Sulapac is a seamlessly sustainable choice

Sulapac is already helping many companies across the globe – from fashion to food packaging – make the change from traditional plastics to bio-based materials.

Pioneering brands are finding Sulapac materials’ blend of beauty and sustainability irresistible. The wide range of industries and applications where our bio-based materials are in use highlights the sheer versatility of Sulapac’s portfolio. Let’s take a quick look at four eco-friendly application examples.

1) Sustainable straws for high-end outlets: Luxury hotels and exclusive establishments in the United Arab Emirates have introduced user-friendly, bio-based drinking straws. Made from wood chips and plant-based binders, the straws are industrially compostable and biodegrade without leaving a trace of dangerous microplastics.

2) Everyday essential items for Marimekko: World-famous design house Marimekko’s Marimade products are crafted from a unique Sulapac plastic alternative with a ceramic look and feel. Everyday objects such as lunchboxes and takeaway mugs are made of responsibly sourced 100 percent bio-based raw materials.

3) Green glamor innovation for cosmetic pencils: Leading global makeup supplier Schwan Cosmetics offers lip liners and eyeliners made of sustainable barrel materials. The game-changing product keeps the sensitive makeup ingredients inside the cosmetic pencil without using any conventional plastic.

4) The world’s most sustainable loudspeaker: Sustainability has never sounded so good. RD Physics, leaders in 3D printed loudspeaker design and manufacturing, presents the Sfaira speaker, made of Sulapac materials that give outer components a natural look and feel and durable protection without leaving a toxic load.

How Sulapac helps industries adopt bio-based material

At Sulapac, we empower industries to make impactful changes for a greener future by ensuring simple and seamless transition from conventional plastic to a sustainable alternative. Our materials can be introduced into existing manufacturing processes without the need to invest in new machines.

We offer comprehensive support to companies that choose Sulapac materials. Technical assistance is available, along with training. For brands switching to Sulapac, we also provide help with commercialization activities.

The endless possibilities of bio-based material

The paradigm shift in bio-based material usage will only accelerate – driven by the factors we mentioned above. So, what kind of industries can benefit from Sulapac’s innovative materials? Here are just a few examples.

Consumer goods: The consumer goods industry is embracing change. Sulapac material allows for the creation of reusable and recyclable products that don’t compromise on design. Imagine disposable cutlery made from sustainable material while maintaining consumer convenience. Well, that already exists – Sulapac offers the most sustainable cutlery on the market.

Electronics: Electronic devices can be packed with non-recyclable plastics and harmful components. Bio-based materials offer a viable alternative. Just picture a plant-based smartphone case that can be fully recycled and leaves no harmful microplastics behind. If consumers keep pushing for greener product options, this future could be nearer than you think.

Automotive industry: The automobile industry is responsible for a significant portion of global emissions and waste. Versatile, bio-based materials could transform this picture for the better in a number of ways. Take car interiors – usually filled with fossil-based plastics, bio-based materials could be used to manufacture door panels, seat covers and dashboards. Bio-based materials would give car interiors a healthier cabin environment (due to the low emission of harmful volatile organic compounds) and a unique, cosy appearance.

Medical devices: Biodegradable surgical tools and eco-friendly prosthetics could reshape the medical landscape. These fossil-free innovations can not only reduce plastic waste and Co2 emissions – they could enhance patient experiences through the use of sustainable products.

Why luxury brands choose Sulapac

So, the future of bio-based materials is really as limitless as your imagination. But what about right now? Luxury items are a particular area of growth for bio-materials.

Sulpac is great for everyday items we all regularly use like cutlery and food packaging. But the material’s beautiful appearance and unique properties also make it a go-to choice for high-end brands, as it offers the perfect balance of beauty and functionality.

For luxury brands – like Sulapac customer Chanel – there can be no compromise on appearance. Sulapac’s aesthetic qualities combine both form and function, offering the perfect balance of beauty and practicality. The materials also mimic nature, leaving no trace of harmful microplastics in the end-of-life, during use or in the production phase.

Even jewellery can be made with Sulapac! Just take a look at Papu Design’s beautiful creations.

Industry certifications guarantee sustainability

Underpinning the endless possibilities of bio-based materials are scientific discoveries, ceaseless innovation – and strict validation criteria that guarantee any claims are accurate and fully justified.

Sulapac materials are certified to meet the most rigorous environmental standards, including:

1) Biobased certification: All of Sulapac’s materials are certified for their biobased content by the USDA BioPreferred® Program and ASTM D6866, guaranteeing that our materials are derived from renewable, plant-based sources.

2) BPI recognition: Sulapac materials are either already recognized by BPI ASTM D6400 as industrially compostable or are currently gaining the certification.

3) ISO 9001 and ISO 14001 certification: Sulapac holds ISO 9001 and ISO 14001 certifications, reflecting our commitment to ensuring that our operations have the lowest possible impact on the environment.

4) FSC-Certification: Sulapac’s FSC-certification demonstrates our dedication to responsible sourcing of materials. We’re continually expanding our FSC-certified product range.

Sulapac’s sustainable materials will continue to drive the renewable revolution

As consumers, producers and brands make ever-more sustainable choices, bio-based materials are becoming more commonplace. As new alternative materials emerge, it must be noted, that only bio-based materials that are also truly biodegradable, can effectively eliminate microplastic pollution.

Sulapac’s continuing commitment to make this sustainable transition seamless and simple is also an investment in the planet’s future. The possibilities of renewable, biodegradable and recyclable materials really are endless. We are already helping companies from luxury to cutlery to ditch conventional plastic and can’t wait to see what tomorrow brings.