Replacing ABS plastic sustainably

ABS plastics are widely used from cosmetics packaging to 3D printing filaments, even though there is a significant cost for the environment involved. ABS plastics can be difficult, sometimes impossible, to recycle. This has led a growing number of companies to seek sustainable replacements for ABS. Legislation is also impacting this demand. So, let’s find out what are the challenges with ABS and discover what green alternatives to ABS are out there.

How ABS became ever-present

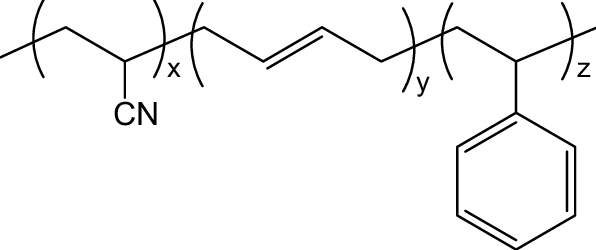

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic whose strength, versatility, and durability mean it’s found in a vast range of products. Some of the most common include automotive, electronics, consumer goods, healthcare, construction, and 3D printing filaments.

The manufacturing and application benefits of ABS are undeniable. Unlike other plastics that deform, ABS has resounding dimensional stability, keeping its shape and size throughout its lifespan. This means products made from ABS maintain their intended dimensions.

ABS is also tough. Its high resistance to impact makes it a solid choice for products that need to be strong and durable, such as electronic housings. ABS may extend service life and lessen the need for repairs as it can take stress and impacts without breaking.

ABS is resistant to a wide range of chemicals. This resilience is essential to applications that face frequent exposure to harsh chemicals. Everything from car parts to household appliances (like refrigerator and dishwasher components), medical equipment (hospital bed parts and lab equipment), and industrial equipment such as storage tanks.

Finally, ABS has low production costs and is easily machinable.

ABS’s manufacturing benefits come at a major environmental cost

So, ABS plastics are long-lasting, strong, and versatile. But what about the downsides? ABS can have significant negative environmental impacts. Let’s break them down.

– Chemical pollution: ABS plastics are composed of chemicals, including styrene, acrylonitrile, and butadiene. These are hazardous to human health and the environment. As ABS plastics degrade over time, these chemicals may leach into the environment with potentially devastating effects on ecosystems and wildlife.

– Human health: The leaching of chemicals present in ABS plastics also poses major human health concerns. Hazardous chemicals may be ingested, inhaled, or come into contact with skin. Exposure may lead to a range of health issues, from breathing problems to reproductive and developmental toxicity, neurotoxicity, and carcinogenicity. People at particular risk from ABS plastics include those involved in the manufacturing, processing, or recycling of ABS plastics.

–Microplastic pollution: As ABS plastics break down, tiny particles (known as microplastics) are formed. These can end up in water bodies and soil, where they might be absorbed by marine life or land animals. Along with damaging the ecosystem, these microplastics may enter the food chain, eventually impacting human health.

– Bioaccumulation: Some of the chemicals in ABS plastics may accumulate in the tissues of living organisms. This bioaccumulation may increase the toxicity of the chemicals and present a threat to an ecosystem’s health.

Fossil-fuel based ABS is bad news for the planet

As a fossil-fuel based plastic, ABS also has several negative implications related to resource use.

– Dependency on fossil fuels: The production of ABS is particularly reliant on petroleum. The primary raw materials (acrylonitrile, butadiene, and styrene monomers) are derived from petroleum-based feedstocks. The extraction and processing of these fossil fuels come at significant environmental costs, such as habitat destruction, pollution, and carbon emissions.

– ABS has a large carbon footprint: The production of ABS is carbon-intensive, requiring energy-heavy processes that rely on fossil fuels. This means that every kilogram of ABS plastic yields a substantial carbon footprint, adding to the amount of greenhouse gases in the atmosphere.

– ABS can be harmful throughout its lifespan: As a nonbiodegradable plastic, ABS may end up in landfill, contributing to environmental degradation, or being incinerated, emitting even more greenhouse gases.

Why recycling ABS is so hard

So, there are major concerns related to ABS and sustainability. But wait – surely recycling can reduce some of ABS’s environental impact? Well, not really. Recycling ABS comes with challenges of its own, from the tricky to the almost impossible.

– ABS has a complex composition: ABS plastics are composed of multiple materials whose components are chemically bonded. This makes separating them for recycling difficult. Advanced equipment must be used for recycling to be successful, adding layers of complexity and cost to the whole process.

– ABS is often contaminated: The contaminants that ABS plastics often come into contact with – like oils, chemicals, and food – degrade the quality of recycled ABS. These contaminants can also pose a health risk if not properly removed. Cleaning ABS to render it suitable for recycling is labor-intensive and may not even be feasible in certain settings.

– ABS has poor thermal stability: This leads to degradation when subjected to high temperatures during recycling. Other problems caused by this may include thermal decomposition, which can release toxic fumes and degrade material properties. ABS’s thermal limitations place restrictions on the types of recycling methods that can be used.

– Recycled ABS has a lack of market demand: Even when the problems of recycling ABS are overcome, there may be limited demand for the materials in the market. Virign ABS has better consistency and performance, meaning manufacturers may favor this over recycled ABS.

Legislation makes finding ABS replacements a necessity

Along with all these recycling limitations and obstacles, new legislation will increasingly restrict the use of ABS plastics.

For example, the French Parliament has taken a significant step towards environmental protection by banning single-use packaging composed (wholly or partially) of styrenic polymers or co-polymers – such as ABS. This will come into effect in 2025.

Biobased Sulapac Luxe materials – the sustainable ABS replacement

The reasons to replace petrol-based ABS are clear – the high carbon footprint, the environmental toll, the difficulties of recycling the material. What has been less clear until now is whether biobased alternatives can replace ABS and in which applications and with what investments.

Sulapac Luxe and Luxe Flex materials provide the solution for cosmetic packaging. Here’s why:

Seamless integration: Sulapac Luxe and Luxe Flex materials can be integrated into existing manufacturing processes. Even though mold modifications may be required, the costs of the transition remains reasonable compared to a material which would require a completely new machinery.

Aesthetic appeal: While being biobased, biodegradable and eco-friendly, Sulapac materials can achieve the same look and feel as ABS plastics, so there’s no compromise on aesthetics.

Comparable performance: Sulapac Luxe and Luxe Flex materials have similar mechanical properties to ABS, delivering the needed performance for cosmetic applications but eliminating toxic substances and persistent microplastics associated with ABS plastics.

High biobased content: All Sulapac materials have maximized biobased content, significantly reducing reliance on fossil fuels and contributing to a lower carbon footprint.

Efficiently recyclable: Sulapac Luxe and Luxe Flex materials can be made with recycled content (Sulapac Luxe with up to over 50% recycled biopolymers and Luxe Flex with over 70% recycled biopolymers). The materials’ suitability for chemical recycling has been independently verified by third parties, facilitating a closed-loop system that minimizes waste.

By transitioning to sustainable alternatives like Sulapac Luxe and Luxe Flex materials, we can stop the spread of persistent microplastics and reduce materials’ environmental impact. If you want to learn more about the sustainable replacements to ABS, reach out to our experts today!

Sulapac Ltd is an award-winning material innovation company bringing solutions to the global plastic crisis. By replacing conventional plastic with sustainable, beautiful, and functional Sulapac materials, companies can reduce their carbon footprint, eliminate microplastic pollution, and advance the circular economy. The Helsinki-based company was founded by three scientists in 2016 and serves customers across various industries on three continents. Investors behind Sulapac®, the patented material innovation, include CHANEL and Sky Ocean Ventures.