The reusable tableware showdown: Sulapac Solid vs. conventional plastics

What if there was a material that could redefine reusable cups and tableware — 100% bio-based, food-safe and durable, endlessly recyclable, dishwasher safe, and free from permanent microplastics? It may sound too good to be true, but with Sulapac Solid, it’s a reality.

The environmental impact: conventional plastics vs. Sulapac Solid

Plastic is designed to last. Its durability is precisely why conventional materials such as Polypropylene (PP), Polycarbonate (PC), and High-density polyethylene (HDPE) are widely used in everything from reusable cups and tableware to food containers. Unfortunately, plastic’s durability also means a lasting impact on nature. Conventional plastic materials, typically made from fossil fuels, not only take centuries to degrade but also release microplastics, posing a risk to human health and wildlife.

Sulapac Solid, on the other hand, is a 100% bio-based and biodegradable injection molding material made from biopolymers and natural clay minerals. It doesn’t emit lasting microplastics at any stage of its lifecycle and has a significantly lower carbon footprint compared to fossil-based plastics. Sulapac Solid has been tested for PFAS compounds with no such ‘forever chemicals’ detected.

Solid by design, sustainable by nature

One of the key challenges Sulapac Solid tackles is finding the balance between durability and sustainability. This rare combination has been achieved through extensive research and material development, led by Sulapac’s team of polymer science and chemistry experts.

Sulapac Solid resists wear and tear, maintaining its premium look and feel even after repeated use.

From cups and plates to bowls, lunchboxes and trays, products made from Sulapac Solid can withstand over 200 washes without degradation in quality, drying faster and resisting scratching and staining better than some of their conventional plastic colleagues. They’re also dishwasher safe.

Sulapac Solid combines the best characteristics of plastics and ceramics, offering a pleasant premium touch while remaining lightweight and durable. With branding options, including customizable colors and logo printing, it’s a sustainable choice that strengthens brand identity.

A truly circular solution

Besides microplastic pollution, one of the major issues with conventional plastics is their recycling limitations. Most plastics are mechanically recycled (if recycled at all), but this process leads to a decline in material quality. Plastics degrade with each cycle, and different material grades are mixed during the recycling process. This results in a loss of traceability and limits their reuse for high-quality applications such as food contact items.

Sulapac Solid, by contrast, can be efficiently chemically recycled. This process breaks the material down into monomer building blocks, which are then purified and re-polymerized. This way, the material maintains its high quality through every cycle, allowing it to be endlessly reused for food contact and other applications, where the material’s purity is crucial.

If Sulapac Solid accidentally ends up in nature, it breaks down into CO2, water, and biomass at a rate similar to that of a tree leaf or natural wood, all without burdening the environment with hazardous chemicals.

In Finland, selected Burger King and Rax restaurants as well as the world’s leading startup event Slush have already validated the performance of reusable Sulapac Solid cups.

Also companies operating in passenger transport industry as well as sports arenas and catering companies have expressed their keen interest in using Sulapac Solid. First pilot projects are ongoing and we are eagerly waiting for the first public launch within these categories.

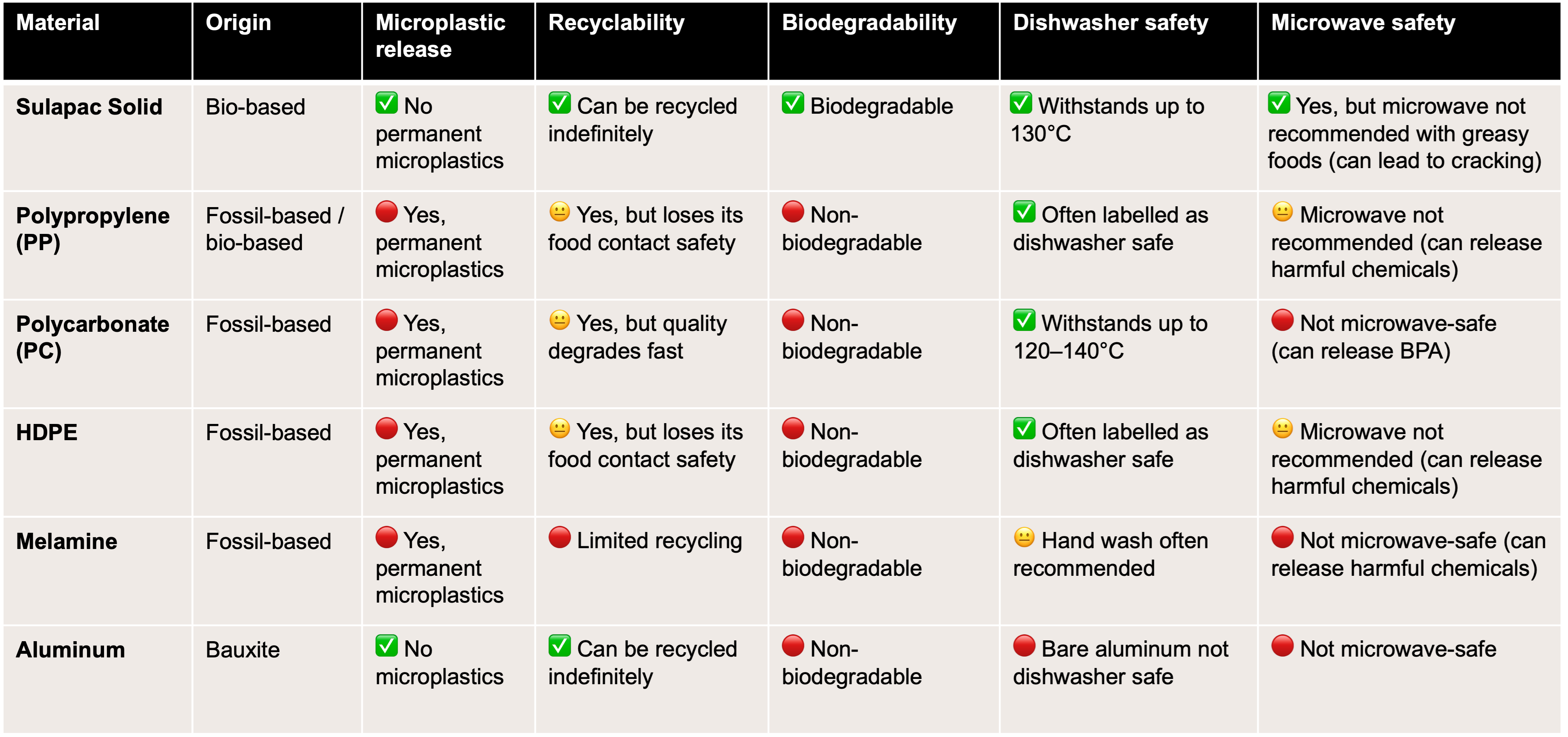

Reusable tableware materials—see the difference

Now, let’s take a closer look at how Sulapac Solid compares with other commonly used materials in reusable cups and tableware.

Safety first: with Sulapac Solid, no worries about harmful substances

The transition from single-use plastics to reusable alternatives is not just a passing trend; it’s an essential shift toward a more sustainable future. With new regulations imposing stricter standards, the demand for environmentally friendly materials in everything from kitchenware to food packaging is growing.

Sulapac Solid undergoes stringent testing to meet the highest food contact safety standards, ensuring a cleaner, safer alternative—for both the planet and people.

The future of reusables is green

Sulapac Solid holds immense potential across industries like food and travel services, where reusable options are becoming the preferred choice over disposables.

Sulapac Solid outperforms conventional plastics from sustainability and safety to recyclability. As we move toward a more planet-friendly future, bio-based and biodegradable materials offer the perfect balance of environmental responsibility and high performance.

Ready to make the switch? We’d be happy to raise a toast to a greener future with you—using a Sulapac cup, of course. Contact us to find out more!