The toxic truth about plastic recycling

Plastic recycling doesn’t work the way you think it does. The very process of recycling can release large quantities of harmful microplastics into the environment. Additionally, recycled plastic has been found to contain toxic chemicals, including pesticides and pharmaceuticals, which present risks to recycling workers and consumers, as well as to the environment.

Plastic recycling is not the solution for plastic pollution for several reasons. Firstly, microplastics are spread to the environment during the recycling process, even when a filtration system has been installed. Secondly, the recycling process of conventional plastic is inefficient, and unsustainable, whether done mechanically or chemically. Finally, recycled plastic contains hazardous chemicals posing a severe health threat to people and the planet. As a result, scientists from the University of Gotherburg state that “there are no plastics that can be deemed safe or circular”.

Plastic recycling is ‘incompatible with a circular economy’

Recycling as such is an incredibly important piece of the puzzle of tackling global warming and biodiversity loss. It can reduce the demand for virgin raw materials, cut down the waste headed for incinerators or oceans, and pave the way to a global circular economy.

But unlike metal or glass recycling, conventional plastic recycling faces several challenges. According to Greenpeace, “Plastics are inherently incompatible with a circular economy.”

So, what makes plastic recycling so tricky?

Why plastic recycling is broken

Only 9 percent of annual plastic waste is recycled. And even for this amount, there are many challenges to overcome.

Firstly, there are thousands of different types of plastic, each with its own makeup and characteristics. These various chemical additives and colourants cannot be recycled together.

Technological limitations of current recycling technology also present a major stumbling block. For now, mechanical recycling remains the only commercial recycling process for plastic adopted on a large scale. This means plastics that cannot be recycled mechanically are most likely burnt or end up into landfills.

Another downside of mechanical recycling is quality degradation. One piece of plastic can typically be recycled only once or twice before it’s no longer reusable.

Market demand is another challenge. Due to the material degradation inherent to plastic recycling, some industries prefer to use cheap, fossil-based virgin plastics. These can cost less than recycled materials.

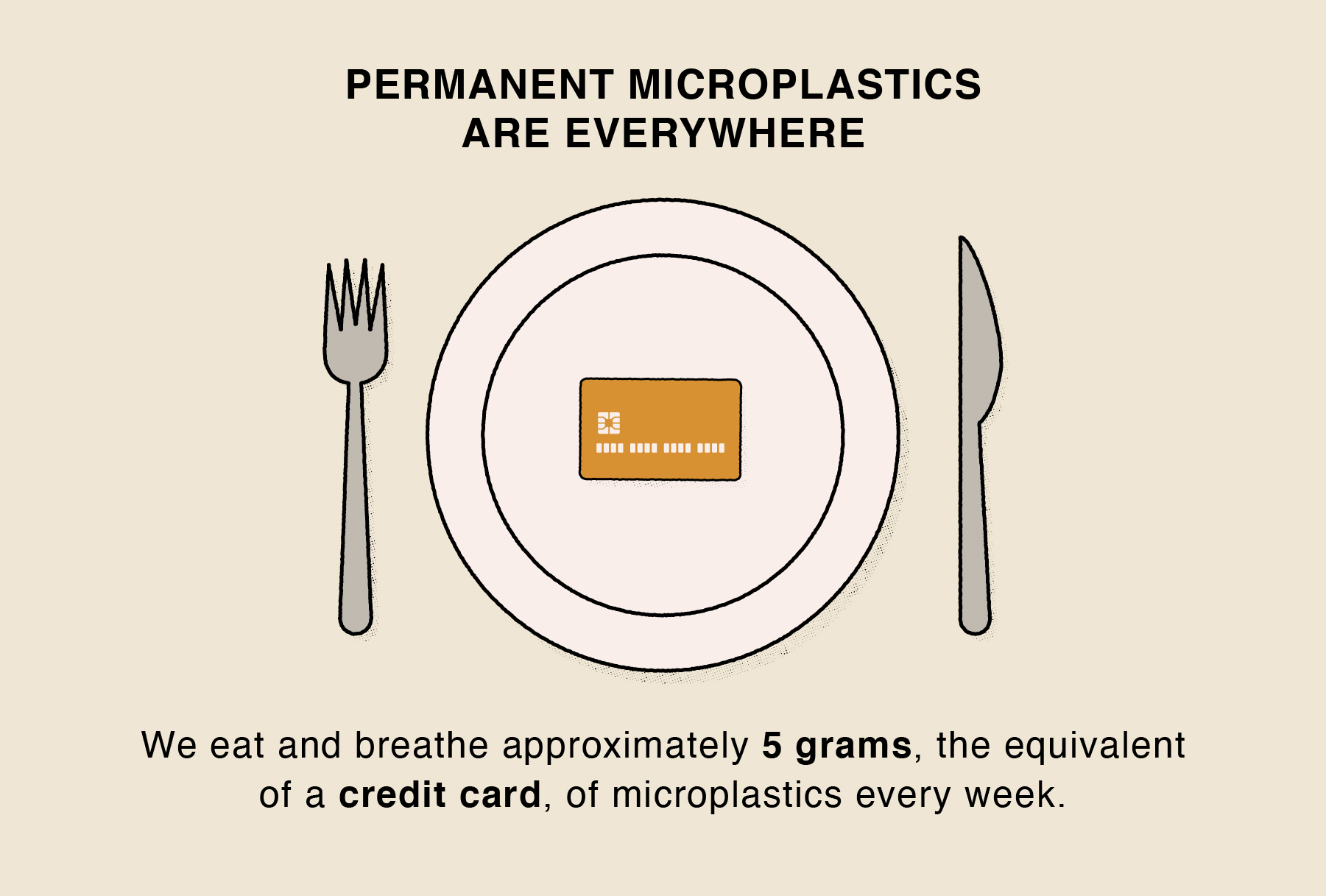

Finally, there’s the elephant in the room: recycling plastic can actually spread microplastics into the environment.

Plastic recycling as a source of microplastic pollution

An awakening illustration of recycling’s role in spreading microplastics throughout the environment can be found in a recent peer-reviewed study. In the study, a UK-based mixed plastics recycling facility was examined for the release of microplastics. Shockingly, the study found that between 6 to 13 percent of plastic processed in recycling may be released into water or the air as microplastics.

Recycled plastic is toxic

When plastics are recycled, they can contain a toxic cocktail of chemicals that makes them unfit for food-grade and other consumer uses. Dangerous chemicals make their way into recycled plastic materials from a variety of sources. Greenpeace has identified the following three ‘uncontrollable poisonous pathways’:

- Toxic chemicals in new virgin plastic materials: When plastics are made with toxic chemicals and then recycled, the toxic chemicals can transfer into the recycled plastics.

- Leaching of toxic substances into plastic waste: Plastics absorb contaminants from the waste stream leading to recycled materials containing a cocktail of toxic chemicals.

- New toxic chemicals created by the recycling process: Heating of plastics during the recycling process may produce new toxic compounds that transfer to the recycled material.

No such thing as ‘safe’ plastic

Further findings lead to the question: can any plastic be considered safe?

In a recent study (led by the University of Gothenburg), researchers analyzed hundreds of plastic pellets derived from plastic recycling facilities in Africa, South America, Asia and Eastern Europe. The compounds found in these included pesticides, medicines, industrial chemicals and plastic additives.

Toxic chemicals are present in the production of all plastics, and plastics absorb other chemicals during use. This means that no plastic can be truly considered safe even in closed-loop plastic recycling systems.

Recycled plastic and food contact

Recycled plastics also present severe issues in terms of food contact. A comprehensive study has found that recycled and reused food contact plastics can be vectors for hazardous chemicals like endocrine disrupters and carcinogens. The study examined chemicals in food packaging, cutlery, plates and other items such as bottles.

The study emphasized that recycling plastics can also lead to unintended negative impacts because hazardous chemicals can be released during reuse and accumulate during recycling. The accumulated chemicals in recycled material can transfer from packaging into food, exposing humans to toxins.

Another alarming find was the use of illicit recycling. This is where non-food grade plastic containing toxic compounds such as flame retardants is utilized in recycled food packaging.

If plastic recycling is broken, what choices do consumers have?

Indisputably, the scale of the problem requires a systemic change. Still, there is something you can do as a consumer and an individual as well to protect your health and the environment.

- minimize the use of conventional plastic

- when ordering out, opt for biobased reusable takeaway containers made of a material with guaranteed chemical safety

- select goods packed in sustainable alternative materials instead of conventional plastic

- buy things package-free when possible

Additionally, we can urge policymakers to take bolder measures to cut back on fossil-based plastics, and we can pressure companies to replace plastic with better alternatives. In the end, a transition to safe and circular plastic alternatives must take place in order to keep our planet and ourselves healthy.

Sustainable plastic alternatives offer a way out of the plastic crisis

Plastic recycling is not the answer to the plastic pollution crisis. Moving to plastic alternatives is a necessary step.

Sulapac is a biobased plastic alternative that has a low carbon footprint and can be endlessly recycled in a safe and efficient polymer-to-polymer process without a worry about microplastics or toxic accumulation. Sulapac biodegrades without leaving permanent microplastics or toxic residues behind. Most Sulapac material grades are industrially compostable, some also home compostable. Sulapac also has safe, sustainable and circular options for reusable items.

The production of Sulapac strictly avoids using any harmful additives typically found in traditional plastic production. The innovative polymer-to-polymer recycling process stands apart for its efficiency, consuming less energy and eliminating the need for hazardous chemicals while providing excellent yields. Through this process, carbon stays in the circulation almost endlessly. This is not the case in the mechanical recycling of conventional plastic, which relies on constant virgin raw material inputs, keeping the oil drillers busy.

By making responsible choices today, we can help shape the course of tomorrow. The spread of microplastics and increasing toxic load are unpleasant facts that we all must face. Switching to sustainable plastic alternatives and reducing the amount of plastic we use is one of the best ways we can help build a cleaner future.

Sulapac Ltd accelerates the plastic waste-free future by helping companies replace conventional plastic with sustainable, beautiful and functional materials that are circular by design. The company was founded in 2016 by three scientists Dr. Suvi Haimi, Dr. Laura Tirkkonen-Rajasalo and Dr. Antti Pärssinen, and was ranked one of Europe’s 100 hottest startups by WIRED UK in 2018, 2019 and 2021. Investors behind Sulapac®, the award-winning, patented material innovation include CHANEL and Sky Ocean Ventures.